Semi-Truck A/C Repair in Dallas, TX – Why Your System Fails?

Looking for fast and reliable semi-truck A/C repair in Dallas, TX? A/C failures in heavy-duty trucks often stem from compressor breakdowns, leaks, low refrigerant, or electrical malfunctions. Our certified diesel mechanics in Dallas specialize in emergency semi-truck A/C repair and preventive maintenance to keep your cabin cool and your fleet on the road.

Key Indicators of Truck Air Conditioning Problems

When you notice unusual cabin temperatures, weak airflow, or strange noises, it’s time for a semi-truck A/C diagnostic service in Dallas. Early detection saves fleets from costly breakdowns and ensures your drivers stay comfortable during long hauls.

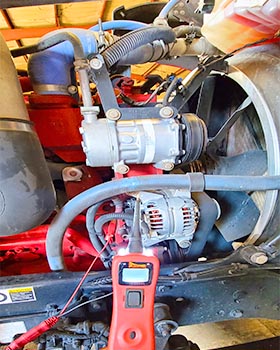

Semi-Truck A/C Leak Repair & Compressor Replacement

Leaks from hoses and seals are common in diesel truck A/C repair. Exposure to harsh road conditions makes it worse. Our Dallas shop offers semi-truck AC compressor replacement, condenser repair, and leak detection with OEM and aftermarket parts backed by warranty.

Emergency Same-Day Semi-Truck A/C Repair Dallas, TX

Stuck on the road with no cold air? Our emergency semi-truck A/C repair service in Dallas provides fast on-site fixes for 18-wheelers, commercial trucks, and fleet vehicles. From semi-truck fleet A/C maintenance to full system replacements, we’re your trusted partner in keeping your trucks running cool.

Sounds and Symptoms: Diagnosing a Faulty Truck A/C Condenser

A noisy A/C, reduced cooling efficiency, and excessive pressure loss are key indicators of a condenser issue in your semi-truck. These signs suggest it's time for a thorough inspection to ensure your system operates at its best.

Spotting Issues with Your Truck's A/C Compressor

Identifying a malfunctioning A/C compressor involves checking for specific signs such as blown fuses, gas leaks, or oil leaks, which are telltale indicators of service needs. These symptoms suggest an immediate need for professional assessment and potential repair to ensure your system's optimal performance and durability.

Semi-Truck AC System Repair FAQs

Over time, issues like low refrigerant, a faulty compressor, or a clogged condenser can cause your truck’s AC to blow hot air. At Salazar Semi-Truck Repair Inc., we offer full diagnostics and quick fixes to restore cold air fast — even during long hauls.

Signs include loud noises, weak airflow, or no cool air. If your AC system fails to activate or cool consistently, your compressor may be worn out. Our expert techs in Dallas can inspect and replace faulty compressors quickly.

Weak airflow often points to a clogged cabin filter, blower motor failure, or evaporator issues. We offer same-day inspections to pinpoint the problem and get your cabin cool again.

Most heavy-duty trucks need an AC recharge every 2–3 years, depending on usage. We recommend regular inspections to check freon levels and prevent system strain or failure.

Absolutely. Salazar Semi-Truck Repair Inc. provides on-shop emergency AC services throughout the Dallas area. Whether you're stuck with no cold air or facing a freon leak, our team is ready to get you back on the road quickly.

We inspect the compressor, condenser, evaporator, blower motor, filters, and refrigerant levels. Whether it’s a minor leak or full system failure, we offer transparent quotes and fast service to keep you on the road.

Schedule Your Semi-Truck A/C Service in Dallas Today

Call Salazar Semi-Truck Repair Inc. for same-day semi-truck repair in Dallas. We handle fleet truck A/C service, heavy-duty diagnostics, and preventive maintenance. Your comfort and uptime are our priority.